Machine fleet

Tecnovimec boasts a fleet of machine tools designed to offer the customer the most suitable solution, resulting in an excellent final product. Additionally, we handle material supply and cutting

Milling and Drilling Department

BRETON MATRIX 800 5-AXIS

TECHNICAL SPECIFICATIONS

- X-axis: 2000 mm

- Y-axis: 1600 mm

- Z-axis: 800 mm

- A-axis: -105° / + 105°

- C-axis: 360°

- Max size: 2000×2000

DESCRIPTION

The BRETON MATRIX 800 5-axis offers unparalleled precision and perfection in mechanical operations. The working platform measures 2000 x 2000 mm, with axis strokes of X = 2000, Y = 1600, Z = 800, and a rotating head with C = 360° capability, powered by a 24,000 rpm motor.

Equipped with CAD-CAM support and a high-performance numerical control system, this machine tool represents the pinnacle of excellence for complex mechanical machining tasks.

RX6005AX 5-AXIS MACHINING CENTER

TECHNICAL SPECIFICATIONS

- X: 885 mm

- Y: 800 mm

- Z: 500 mm

- A = -30° / + 120°

- C = 360°

- Max diameter: 600 mm

DESCRIPTION

The BRIDGEPORT 5-axis machining center represents the latest generation of technology, where mechanical operations achieve perfection and precision. The work table has a diameter of 600 mm, with axis strokes of X = 900, Y = 800, Z = 500, A = -30° / + 120°, and C = 360°.

Supported by CAD-CAM integration and high-performance numerical control, this machine tool stands at the forefront for tackling the most intricate mechanical machining tasks.

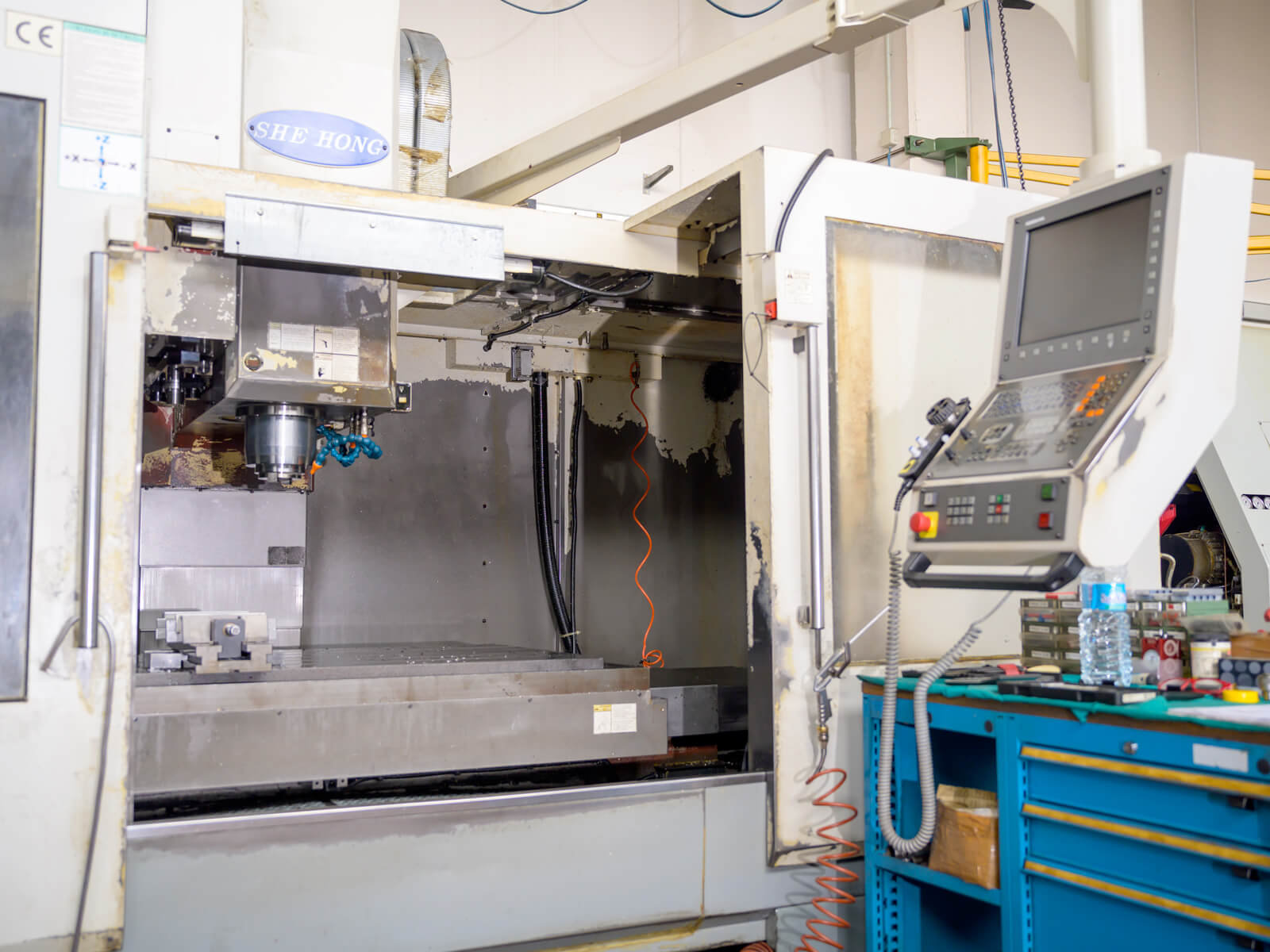

SHE HONG VMC 1600 MACHINING CENTER

TECHNICAL SPECIFICATIONS

- X-axis: 1600 mm

- Y-axis: 800 mm

- Z-axis: 660 mm

- C-axis: 360°

- Max diameter: 450 mm

- Max length: 1000 mm

DESCRIPTION

For 3 and 4-axis operations, we have a vertical machining center with dimensions of X 1600, Y 800, Z 800. The continuous horizontal 4th axis allows us to work on round pieces up to a diameter of 450 mm and a maximum length of 1000 mm.

The robustness of the machine and the BT50 tool attachment enable us to perform complex machining tasks with significant material removal, without compromising on finishing precision.

DMG MORI DMU 90P 5-AXIS MACHINING CENTER

TECHNICAL SPECIFICATIONS

- X-axis: 900 mm

- Y-axis: 1050 mm

- Z-axis: 850 mm

- A-axis -30° / + 180°

- C: 360°

- Max diameter: 1000 mm

- Max height: 1450 mm

- Integration: Heidenhain TNC 640

- Rotary table: 900 × 700 mm

DESCRIPTION

The DMG MORI DMU 90P 5-axis continuous machining center features the latest generation Heidenhain TNC 640 CNC system. Its new ADP motion control system is optimized for superior surface finish and faster machining (block processing time under 0.5 ms).

It guarantees maximum long-term reliability and absolute precision. The rotary table measures 900 × 700 mm, with axis strokes of X = 1000, Y = 1050, Z = 850, powered by a 15,000 rpm motor.

Turning Department

DART 350 TC LATHE

TECHNICAL SPECIFICATIONS

- Max diameter: 350 mm

- Max length: 600 mm

DESCRIPTION

This lathe can perform turning operations up to a diameter of 350 mm and a maximum length of 600 mm. A tailstock is mounted to keep the machining stable.

PUMA 400 LMA LATHE

TECHNICAL SPECIFICATIONS

- Max diameter: 560 mm

- Max length: 2000 mm

- Steady rest min 35 mm/max 250 mm

- Motorized tool turret

DESCRIPTION

This CNC lathe features a turret with motorized tools with a power of 7.5 kW. The workpiece dimensions it can handle are: maximum turnable diameter under carriage 560 mm | maximum rotating diameter on the bed 770 mm | turnable length from self-centering chuck 2,000 mm.

It is equipped with a tailstock and a movable steady rest that supports diameters from 35 mm to 250 mm. It’s a recently built lathe and adopts a state-of-the-art Fanuc numerical control, 21i-tb.

HWACHON HI-ECO 45 LATHE

TECHNICAL SPECIFICATIONS

- Max diameter: 700 mm

- Max length: 2000 mm

- Steady rest min 50 mm/max 315 mm

- Motorized tool turret

DESCRIPTION

This CNC lathe features a motorized turret, highly powerful, and reliable. It can handle diameters on the bed up to 700 mm for 2000 mm. A tailstock is mounted to keep the machining stable.

It is equipped with a steady rest supporting diameters ranging from 50 mm to 315 mm, suitable for heavy material removal and large diameters. This machine tool has all the characteristics for achieving excellent results on the final product.

MANUAL MACHINE TOOLS

TECHNICAL SPECIFICATIONS

- Max diameter: 280 mm

- Max length: 1500 mm

- Steady rest: 200 mm

- Radial drill arm reach: 1500 mm

DESCRIPTION

For simple and quick machining needs, we have an OMG Zanoletti 280 manual lathe, with a maximum bar passage under the carriage of 280 mm in diameter and a length of 1500 mm.

For drilling large diameters and depths, our radial drill offers a reach of 1500 mm.

Wire EDM Department

FANUC ROBOCUT Mod. Alfa 1 i E

TECHNICAL SPECIFICATIONS

- Max workpiece dimensions: 1050x820x300 mm

- Working strokes: XY: 600×400 mm

- Z-axis strokes: 310 mm

- Taper cutting: 20°/150 mm

- Wire diameter: 0.25 mm

DESCRIPTION

Wire EDM utilizes electrical discharges on a brass wire to enable the creation of precision machining with very tight tolerances. It provides an effective solution for the production of high-quality parts.

Cutting Department

CNC DOUBLE COLUMN AUTOMATIC BAND SAW

TECHNICAL SPECIFICATIONS

- Max cutting diameter: 400 mm

DESCRIPTION

Tecnovimec offers a CNC double column automatic band saw capable of cutting diameters up to 400 mm.

This saw features a device for misting oil onto the blade, facilitating cutting of tubes and other materials where chip removal presents particular challenges.

Welding Department

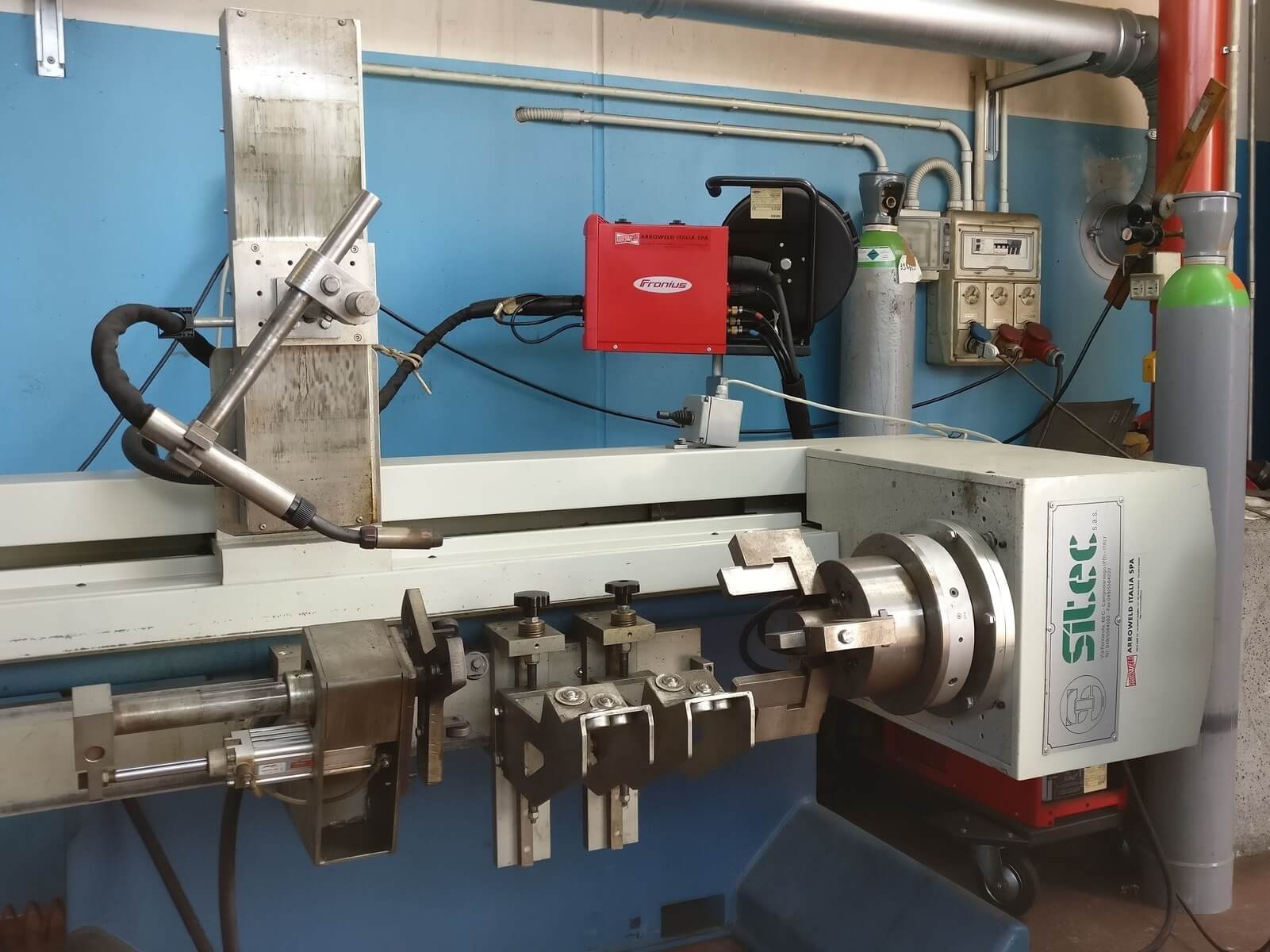

ITV SL 600 CN (tilting lathe)

TECHNICAL SPECIFICATIONS

- Max diameter: 400 mm

- Max length: 1000 mm

DESCRIPTION

We are equipped to weld cylindrical parts ranging from 30 mm to 400 mm in diameter, with a maximum length of 1200 mm. Manual welding is also available upon request.